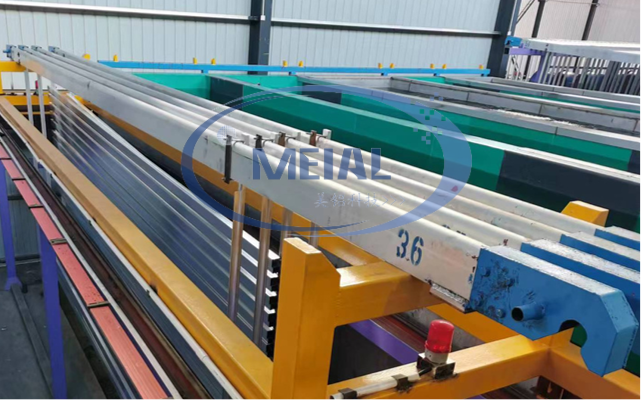

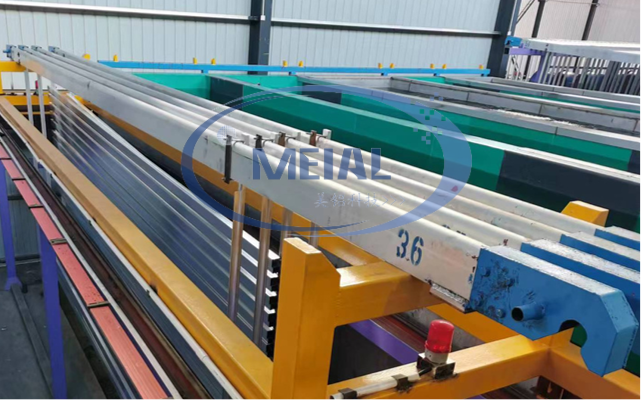

HIGH-END CUSTOMIZED ANODIZING PRODUCTION LINE SUFACE TREATMENT EQUIPMENT

(Horizontal Anodizing Line)

(Horizontal Anodizing Line)

Anodizing Pruduction line of Aluminium Profiles Surface

Pretreatment

Anodizing And Colouring Production Line Of horizontal Surface

Treatment

This proposal is designed for aluminum profiles horizomtal

anodizing production line.

一.Product Description:

| Type: | anodizing and colouring fteatment equipment | Advantage: | saving space and energy,lowest cost ,best service |

| Condition: | new brand | Applicable Industries: | Construction projects, manufacturing facilities, retail

establishments, and shops that repair machinery |

| Warranty: | 365 days | Heating power: | natural gas, LNG |

| Voltage: | 380V 50Hz or Customers Local Voltage | After-sales service provided: | Engineers on hand to repair gear abroad |

Feature:Automatic Anodizing Production line for Aluminum Profile

Surface Treatment Equipment.Save gas and Energy,save space.High

quality,high productivity, smooth and durable coating.

二. Design Condition

| 1 | Alloy | Aluminum 6061 to 6063 or others |

| 2 | Anodizing film thinkness | 10~ 15µm micron |

| 3 | Average coverage area | 450m²/T (ton) |

| 4 | Max aluminium profile length | 6500mm |

| 5 | Extrusion ratio | 2.5kg/m² |

| 6 | Working hour/m | 300d/m x 20h/d = 600h/m |

| 7 | Racking system | Two fixtures /rack |

| 8 | Racking operation | Manual |

| 9 | Equipment Usage Rate | 0.9 |

| 10 | Power supply | AC 3phase 380v 50hz |

| 11 | Control Power | AC220V 50Hz |

| 12 | Water supply | 2kg/cm²·G |

| 13 | Hot steam | 6kg/cm²·G |

| 14 | Compressor air | 6kg/cm²· G |

三. Process Tank

| 1 | Degreasing 【Free sulfuric acid 180±30 g/l】 | 1 Tank |

| 2 | Alkaline Etching【Free alkali 40-60g/l,Al3+ 30-120g/】 | 1Tank |

| 3 | Neutralization【Free sulfuric acid180±20g/l】 | 1 Tank |

| 4 | Anodising 【Free sulfuric acid 140-180g/l,Al3+≤20g/l】 | 1Tank |

| 5 | Colouring 【stannous sulfate 3-8g/l,Free sulfuric acid 15-25g/l,PH 0.8-1.2】 | 1 Tank |

| 6 | Medium Temperature Sealing【PH 5-6.5,Nickel ion0.8-1.3g/l,Fluorion0.3-0.7 g/l】 | 1 Tank |

四. Treatment Time Process:

- Degreasing

(1) 6jig(rack)/ tank x 1 tank=6jig(rack)

(2) treatment time: 2-5min - Alkaline Etching

(1) 6jig(rack) / tank x 2 tank=12jig(rack)

(2) treatment time: 3-15min - Neutralization

(1) 6jig(rack) / tank x 1 tank=6jig(rack)

(2) treatment time: 1-5min - Anodizing

(1) 2 jig(rack)/tank x 1tanks = 2jig(rack)

(2) Current density: 130A/m²

(3) Process time: 30min

(4) Unprocess time: 10min

(5) Total time 30+10=40min

(6) Average anodizing layer : 0.36*1.3*30*0.77 =10.81um

- Colour 1

1) Clour process: Mix Salts

2) Quantity:2 jig(rack)/tank x 1tanks = 2jig(rack)

3) Current density: 70A

4) Process time: 2-8min

6. Sealing

1) Sealing menthod: Sealing at Medium or Normal Temperature

2) Quantity:6jig(rack)/tank x 1 tank

3) Process time 10-15min

五. Design Parameter and Setting

1. Anodizing treatment area:

1) Each anodizing process tank need 40min ,where total

jig(rack)/year:

( 2 rack x 1 tank x 60min/h) ÷40min x600 hour =1800jig(rack)

2) Design 42.9m²/jig(rack) . Where every tank is 85.8m²

3) Area treatment/year : 1800jig(rack)x 42.9m² /jig =77220m²

2. Anodizing treatment weight:

Monthly output : 77220m²÷450m²/T*0.9=154.44T≧150T

3. Power consumption:

1) Anodising Tank:100m²/tank* 130A/ m²÷0.9=14444A/tank

Power Rectifier : 15000A =1unit

2) Clouring tank: 100㎡/tank×70A/m²÷0.9 = 7777A/tank

Colour Rectifier : 8000A =1 unit

六,Energy supply and startup

1,Power supply:380V, 3Φ, 50Hz power supply

2,Use high frequency soft switch and convert the electricity very

high efficiency, ≥94%.

3,Electricity modular structure: 12KA/22V for each cabinet, consist

of 4 pcs of 3KA/22V single modular.

4,Direct output voltage: 5% to 100% rated continues adjustable

5,Direct output electric current: 5% to 100% rated continues

adjustable

6,Control system use digital control, high efficiency and stable

output accuracy: ≤±0.2%

7,Soft startup time: 1~999S random setting

8,Soft turn off time: 1~999S random setting

七,Power supply of Electrolysis

1),Power supply of Electrolysis and coloring:3sets/tank×1 tanks 3

sets

2),cooling: water

3),first time power input: 3 phases 380V 50 Hz ± 1 Hz

4),second time voltage output: ± 3~30V

八, Cooling system

1),Cooling unit:209,000 kilocalorie centrifugal machine-direct cooling

2),Cooling tower:600T/h squared tower

3),Cooling water pool:3*3*3m3 8mmA3 Fiber reinforced steel, steel

support in

4),Direct Cooling pump:55kw 600m3 18m

5),Indirect Cooling pump:22kw 250m3 18m

6),Circulating line for cooling water:PVC pipe

九,Heating and temperature controlling system(excluding steam

boiled)

1),Heating of sealing tank:316Lstainless steel pipe,valve,flange

DN40

2),Heating of alkali etching and cooling:Seamless steel pipe,

valve, flange DN40 tank with double pipes 20m2

3),Heating of hot water tank:304 stainless steel pipe, valve,

flange DN40

4),General pipe for steam in the workshop:DN80 seamless steel pipe,

valve, flange about 180m

5),Auto valve and temperature controlling system:5 sets

十,Production Capacity

Monthly Capacity: 3000ton/mouth

十一,Water consumption

1),Input pressure: 0.3mpa

2),Design Flow:80m3/hour actual use: 40m3/hoour

十二. Steam consumption

Flow: 2 tons/hour,

Pressure: 0.8Mpa.

十三,Process Description:

loading,pre-treatment,anodizing,electrolysis,coloring,sealing,hot

water rinsing,dripping and downloading,packing .

Discription for process

1) De = Degreasing

2) Rs = Rinsing,

3) HW Rs = Hot Water Rinsing

4) AE = Alkaline Etching

5) Ne = Neutralization

6) An = Anodizing

7) Cl = Coloring

8) Sl = Sealing

9) MU = Material Unloading

10) Pc = Packing